Why we champion GEX eggshell bio-calcium

Which came first, the oyster or the egg? When we decided to focus on finding the very best plastic-reduction and sustainability solutions in Taiwan, we had no idea that we would end up at eggs. Or more specifically, GEX eggshell bio-calcium.

When we started our mission, the more experts we spoke to, the more it seemed that our number one goal should be to keep as much plastic as possible out of the landfills and oceans, where it does the most harm.

Toward that end, we first talked to a number of bio-plastic producers in Taiwan and China, who were mostly manufacturing PLA. We were excited by this plastic’s ability to biodegrade, but the more we studied it, the more it didn’t seem like the solution we wanted to promote. For starters, this corn-based plastic is expensive, and as the price of corn fluctuates, so will the price of PLA. Bio-plastic is also difficult for the average consumer to tell apart from petroleum-based plastic, so much of it will end up in the recycling bin. This is not ideal as PLA plastics cannot be recycled. Instead, they need to be composted under specific conditions involving nitrates, moisture, and other factors. If consumers do not compost and simply throw PLA away, it will just end up in a landfill alongside the other plastics for 1000s of years, as landfills do not meet the composting conditions. PHA, another biodegradable plastic, looked extremely promising, but it was not mature enough to offer to massive plastic manufacturers churning out jars, bottles, packaging trays, and even toys.

We then considered offering alternatives to single-use plastics, but didn’t see where we could offer anything new to consumers. The market for straws, lids, cups, and stirrers made from materials like bamboo, sugar cane, and others was pretty well covered, and none of these materials could be applied to mass produced, durable plastics.

So, how could we have an impact on the plastic crisis? How could we help those massive companies churning out so many plastic products quickly and affordably reduce their plastic use and keep as much plastic as possible out of the landfills and oceans?

Enter calcium carbonate

Calcium carbonate (CaCO3) is a ubiquitous additive in the plastics industry. It can be added to plastic bags to make them easier to open, and it can be added to any other plastic product to add strength or even  to reduce cost. There are some issues with it, however. Even though it can reduce plastic, it unfortunately is not eco-friendly. CaCO3 is a mined material with a hefty carbon footprint. Manufacturers, then, cannot say that they are being green by using it to reduce plastic content.

to reduce cost. There are some issues with it, however. Even though it can reduce plastic, it unfortunately is not eco-friendly. CaCO3 is a mined material with a hefty carbon footprint. Manufacturers, then, cannot say that they are being green by using it to reduce plastic content.

Another problem is that it is not compatible with all plastics, and it doesn’t bind well with others, making the end product quality quite poor. Manufacturers also don’t care for the additive as, being a hard mineral, it can tear up their expensive machines.

While investigating CaCO3, we came across a bio-calcium carbonate sourced from oyster shells. Being a bio-calcium, when added to plastic, the particles had many more facings for binding with the plastic polymers, making a superior product – so much so that it could reduce plastic content by up to 50%. Bio-calcium could also work with most types of plastic, and as an amazing bonus, products made from it showed antibacterial properties. Most importantly, being sourced from a sustainable resource, it offered a serious reduction to one’s carbon footprint. The only problems that remained were that the material was still quite tough on machines, and that the oyster supply in the world was limited.

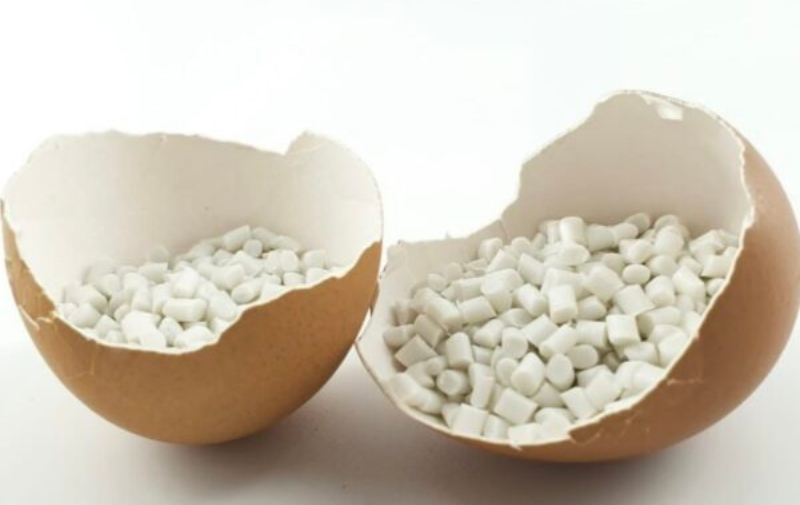

This is when we met GEX, a bio-calcium sourced from chicken eggs (or other poultry) and turned into a plastic-reduction wonder material through a patented process. Coming from eggs, the particles are even smaller (making better products) and softer (not harming machines). The material can still reduce plastic by up to 50%, still produce antibacterial end products, and it can be used with recycled plastics to make 100% virgin plastic-free products that are also much lower in total plastic. When used with recycled plastic, it can reduce carbon emission by nearly 70% compared to virgin plastics.

GEX eggshell bio-calcium is patented in the USA, UK, Australia, China, and Taiwan, and it has been certified by SGS as a carbon and plastic reducer. This means it can be used by companies to make greener packaging, and they can receive eco-certification as well. It can also be used to help companies easily and quickly meet plastic-reduction mandates, something calcium carbonate cannot do. It is easy for manufacturers to work with, and they can cut a quick 25-50% off of their plastic use without having to redesign a bottle or tray, reduce the size of their packaging, or find a brand new material. They simply need to mix GEX into their compound to immediately reduce their plastic use and shrink their carbon footprint.

Game-changing Applications

GEX eggshell bio-calcium is the solution we chose to champion, and we are fortunate to be authorized distributors and representatives of the material. Here are some of the solutions that we have seen made possible:

- Pharmaceutical bottles made from 30% GEX + 70% rHDPE (receiving commendation from the UN for plastic reduction along their SDGs)

- Cosmetic jars and tubes made from 30% GEX and 70%PP (and 70% rPP)

- Foam mats and gym flooring that are 40% less plastic, cheaper, and anti-bacterial

- Trays and industrial packaging with 50% GEX

- Bags (for DELL and HP) made form 50% GEX and 50% recycled plastic.

- GEX + PLA for reduced plastic and biodegradable straws, utensils, etc.

- Industrial buckets, bins, and barriers with a 30% plastic reduction.

- Pallets made of recycled plastic and GEX that pass stringent strength tests.

- And lots more…

So, whether you need to meet a government mandate and take a quick and easy 25% off your plastic use, or if you are a company that wants to have the greenest possible plastic to align with your company’s goals, we humbly offer you an eggshell… and the patented, certified process that turns it into a game-changing material.

Reduce. Reuse. Recycle.

No Comments

Sorry, the comment form is closed at this time.